UV Resistant Additive

In short

Plastic parts tend to change color when exposed to UV light. To make sure a part keeps its true color even when exposed to the sun, post-processing is necessary. At Parts on Demand, we can coat or impregnate the part, using a UV resistant additive.

Finished your design? Make sure to check:

- Deep or narrow internal cavities, the treatment won’t reach those surfaces.

- Large, thin parts tend to warp during the process.

- Maximum dimensions 250 x 250 x 500 mm.

About UV resistant additive

Plastics can oxidize, just like rust in metals. This oxidation over time results in the color of the plastic turning into a creamy yellow. This process in well-known with plastic garden furniture, turning from bright white to a yellowish shade.

The same thing happens to 3D-printed parts. Exposed to sunlight for longer periods of time, white parts will turn yellow, black parts will get a kind of brown sheen.

The cause of this oxidation is not moisture but UV light. We can prevent this by adding a UV resistant additive in the coloring process.

Option one

The first solution is protecting the surface of the parts with a spray coating. Just like you would protect metals with a layer of paint, the same can be done for plastics. A spray coating is used to seal the parts resulting in a surface layer of industrial lacquer. Giving the parts a nice finish and protection against UV.

For technical parts however, a coating is not always the ideal solution. It adds an extra layer, which you need to account for in your dimensions and tolerances. Coated parts need to be handled with care to prevent damaging or chipping the coating. Another type of treatment sidesteps this obstacle. Our option two.

Option two

Just like we can impregnate your parts with a color dye, we can impregnate parts with a UV stabilizer. Or even a combination of both.

Under the influence of pressure and heat the UV stabilizer, as well as the color dye, penetrate the surface of the part. The molecules of the stabilizer react when exposed to UV light and protect the color and the plastic itself.

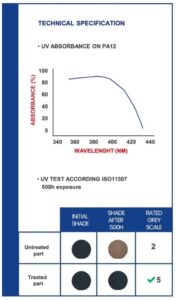

The result is measured in a so called ISO11507 exposure test. This test measures the ‘light fastness’ of the colors, at the start of the test and after 500 hours of UV exposure. The color deviation is graded on a scale of 1 to 5, where 5 means no deviation and 1 means the color has completely faded.

We have performed this test on black parts. An untreated part received a grading of 2 after 500 hours of exposure to a UV light source. The same part with the added UV stabilizer received a grading of 5 after the same 500 hours of exposure. Meaning it has kept its original color without fading.