Holes

In short

In 3D-printing you can include openings and holes in your design. However, you need to consider certain tolerances, and make sure excess printing material doesn’t get trapped in your part.

Finished your design? Make sure to check:

- Internal cavities. Make sure you add exit holes, to remove the residual material.

- Small holes. Increase them by 0,15 mm – 0,20 mm to compensate for shrinkage.

- Make sure holes are standard drill bit sizes if your part requires post-processing.

Gaps

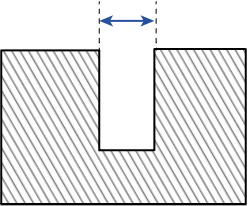

Gap resolution in SLS not only depends on the width of the gap, but also the thickness of the wall in which the gap is printed. Thinner walls allow the resolution of the gaps to increase because material is easier to clear.

Less material helps prevent the laser from fusing too much material due to trapped or radiant heat (known as over-sintering). Thermal shrinkage might also shrink the designed size of smaller gaps on large surfaces.

When creating small parts, be sure to use thinner walls with gaps to avoid over-sintering. Use ribbing for structural support wherever possible, as you would when designing for injection molding. This will help decrease the amount of material in the part, which prevents over-sintering.

Offset thin or irregular gaps 0,15 mm – 0,20 mm to account for shrinkage due to over-sintering and subsequently resulting in a part that is closer to your designed measurements.

Holes

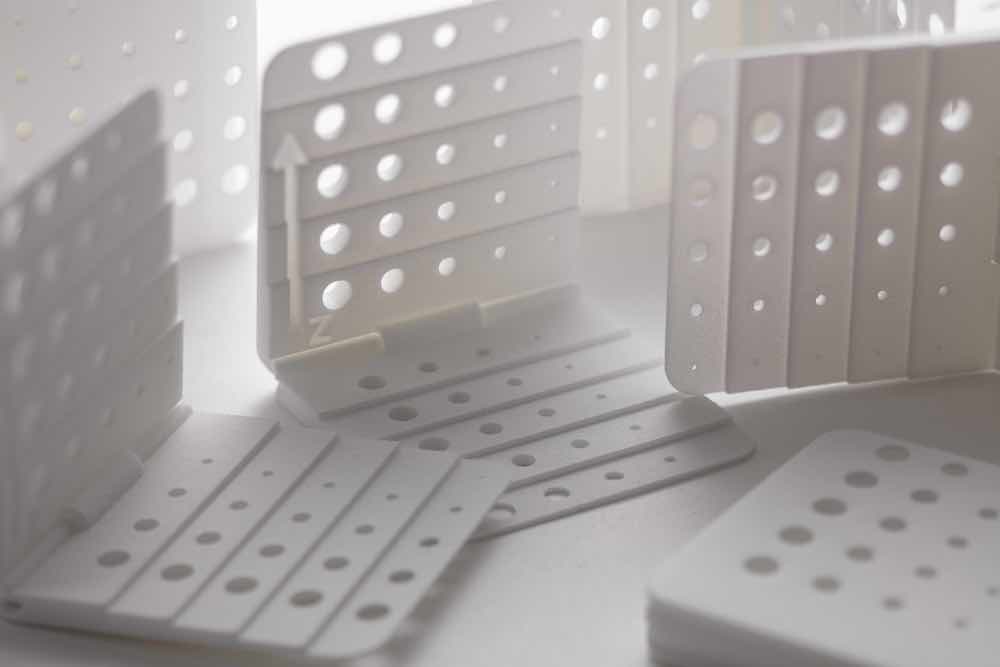

For parts with small holes or internal cavities, it is important to ensure that material can clear from them. Small holes may end up closing, due to over-sintering. This also depends on the thickness of the walls in which they are printed. The thinner the wall, the more easily the hole can be cleared.

If possible, decrease the wall thickness to help clear material and to reduce shrinkage. Add an offset of 0,15 mm – 0,20 mm to the hole to account for shrinkage due to over-sintering.

We recommend designing holes with standard drill bit sizes to ensure exact dimensions. We can open accessible holes larger than 1,5 mm and smaller than 10 mm as long as a standard bit is available. Post-processing is the most reliable way to create precise and accurate holes.

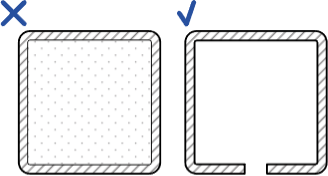

Pockets and cavities

When parts have pockets or cavities, make sure to include openings to allow un-sintered material to exit during the cleaning process. We recommend at least two relief openings of >14 mm in diameter if possible. Situating these openings within the line-of-sight allows for more successful cleaning.

Material may also be difficult to remove from blind screw bosses, tubes, and long holes. We recommend exit holes here as well. Openings can be added along the side of the boss.

At Parts on Demand, we prefer not to build products with fully confined hollow parts (e.g., a balloon), as the un-sintered powder inside such a part cannot be removed. This also applies for parts with exit holes that would be too small to rapidly remove trapped powder (e.g., a saltshaker).