Connected parts

In short

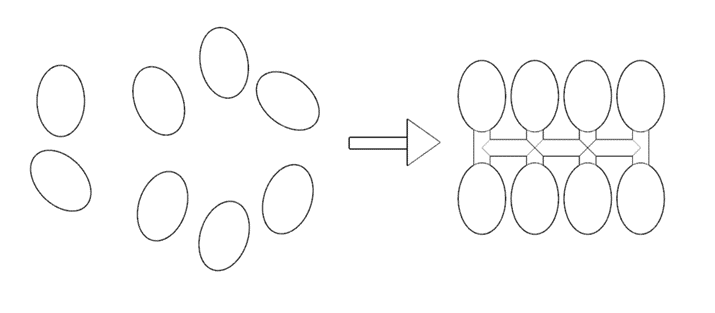

If you want to produce many small parts, it might be beneficial to connect them with a sprue. In this chapter we explain the do’s and don’ts of connected parts.

Risks of connected parts

Printing one connected part instead of many small parts is more efficient. However, there are some major downsides you need to consider:

- With linked parts it is more difficult for us to determine the ideal printing orientation. This means you might end up with parts that have visible layers and less accurate dimensions.

- Linked parts are more difficult to clean, meaning you might find some powder trapped in your parts.

- Linked parts are more difficult to post-process, which might result in an uneven surface finish and patchy colouring.

- Removing the sprue will leave a mark on your part. If the part is colored, removing the sprue will reveal the white inside of the part.

Guidelines

If you require high quality parts, we do not recommend linking your parts together. If you still want to connect your parts, make sure you follow these guidelines:

- The connecting sprue should be >1,5 mm and should be as short as possible. If the sprue is too thin or too long, it will break during the cleaning process and you might not receive the complete set of linked parts.

- Make sure your combined parts all have the same orientation.

- A distance of 1 mm between parts will prevent them from fusing together. You will need to add more distance depending on the geometry. To ensure easy cleaning and colouring between parts, a distance of at least 10 mm is needed.